|

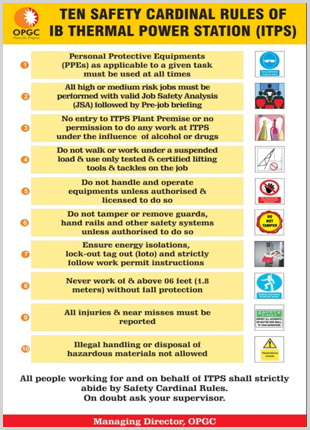

OPGC gives paramount importance to occupational health and safety of its workforce. So, Safety tops the list of OPGC Value system and comes before everything else as OPGC cares for its people and wants them to go home safely after each day’s work. Ten safety cardinal rules are strictly followed right from entry to plant premises till exit.

| |

|

|

|

|

|

| |

|

|

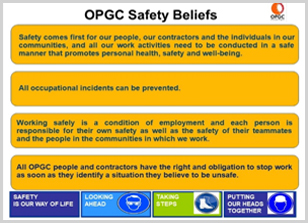

OPGC’s goal has been to make that possible for each OPGC person and partners/service provider by creating and sustaining an incident-free workplace. Personal Protective Equipment like Safety Helmet, Safety Shoe, Safety Glasse, Nose Mask and Earplug are mandatory for employees including visitors while inside the plant. All persons including visitors are safety inducted before entering

the plant. OPGC has been continuing its pro-active Occupational Safety & Health management procedures and nurturing a culture focused on safety. The safety strategy is centred on the belief that all occupational injuries can be prevented and zero harm is achievable. Everybody including visitors has a right to stop the work if they identify a situation, they believe to be unsafe. The approach to safety is defined in the OPGC EHS Policy, Values & Beliefs.

| |

|

|

|

|

|

| |

|

|

OPGC EHS management system is in line with ISO 45001:2018, ISO14001 & Global safety standards help it to achieve a sustainable safety culture. Ensuring the safety and wellbeing of our employees, communities, customers and other stakeholders has been our priority.

In line with the objective to be a leader in safe work premises and practices, OPGC company has an established EHS Manuals, Procedures, Standard Operating Procedures (SOP) and Standard Maintenance Practices (SMP) for human, equipment and process safety. Hazard Identification and Risk Assessment (HIRA) process for both routine and non-routine jobs are carried out and significant risks are eliminated through suitable measures. PTW system and LOTO procedure integrated with the SAP which gives the energy isolation guarantees before doing any maintenance job. HIRA and Job Safety Analysis (JSA) trainings are regularly provided to operation, maintenance and service engineers. All occupational incidents root causes are thoroughly analysed through a dedicated RCA team and recommendations are implemented for preventing the recurrence. Moreover, through internal auditing process, key improvement areas are identified to strengthen workplace safety.

To safeguard the health of our employees, OPGC has an established process to minimise risks and enable effective identification and elimination of work-related hazards. We always give priority to hierarchy of hazard control methods i.e., Elimination, substitution, Engineering control, Administrative and finally personal protective equipment. For that, OPGC has implemented remote breaker rack in and rack out system by using robotic equipment (IRRD) through which human exposure to arc flash is eliminated. Similarly, use of modern technology i.e., drone for inspection of remote areas like healthiness checking of railings at different elevation of stacks, inside boiler and ash lines has been adopted. Physical separation of pedestrians has been constructed & zebra crossing demarcated on the plant roads to improve traffic safety management inside the plant.

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| IRRD |

|

LOTO |

|

FLOOR INSULATION |

IEC (information, Education & communication) materials are circulated through digital mode and through audio visual mode among the employees as well as contractor partners. We provide regular health and safety trainings to improve the effectiveness of our health, safety and emergency management systems. Conducting regular emergency mock drills in presence of statutory authorities & district administrations to review our emergency preparedness.

OPGC has implemented and achieved some key safety initiatives during the recent years: -

- OPGC has implemented safety online portal and safety mobile App i.e. “OPGC Safety Connect” as one step ahead towards use of technology for accident prevention. Daily debriefing of Safety Observations and Incidents in Daily Planning meeting is a routine activity.

- The Middle and top management are leading through examples and leadership visibility at field level is felt which plays a great role in changing human behaviour of workers to improve the safety culture. OPGC has implemented Leadership Safety Assurance Scorecard and Line Manager Scorecard which are also linked to Performance management system.

- Weekly reviewing of EHS performance and safety issues by top management is being carried out.

- Ensured annual & pre-employment health check-ups and tracking of health conditions of employees and contractor partners.

- Periodical Mock drills are being conducted as per statute every year which have been witnessed by statutory authority & mutual aid-partners from nearby industries.

- Internal and External statutory Safety audits are being conducted as per statute and reports are submitted to the statutory authorities.

- Efforts are undertaken to complete outage with zero LTI by establishing a proper outage safety plan. Outage workforces are encouraged by rewarding for their safe behaviour at workplace and establishing a positive safety culture.

- Apex safety committee meetings are being conducted every month and various safety issues are addressed.

- Employees and Contractor partners are rewarded as monthly safety champion during Apex safety committee meetings and also during various safety events throughout the year.

- OPGC has also presented a paper on “Best safety Practices for effective O&M” on 13th Feb’24 during Indian Power Station (O&M conference) conference held at Raipur, which was organized by NTPC

- The accolades received by OPGC on safety performance, of late;

- OPGC (2x210MW) in recognition of its superlative safety culture and practices, has been awarded an international safety award in the “Merit winner” category by prestigious British Safety Council in Year 2022.

- OPGC bagged award of Electrical Safety Award-2023 on 4th National Electrical safety week by EIC(E) cum PCEI, Dept. Of Energy, Govt. of Odisha

- OPGC (2x210MW) received Kalinga Safety Excellence Award in the Gold Category for the performance year -2022 in recognition of best safety practices.

|